FEATURES & SPECIFICATIONS

DESCRIPTION:

Biosafety Cabinets are specialized workstations widely used in clinical, pharmaceutical, life science and industrial laboratories where experiments need highly contaminant free environment. Also known as biological safety cabinets and biohazard safety cabinets, these are made in three different class types such as Class 1, Class 2 and Class 3; in which Class 2 is widely used in microbiology laboratories because it provides protection to both product as well as personal. It is biosafety level factor which decides which BSC should be used in laboratory. These cabinets are considered safer than other clean benches because such BSCs effectively eliminate risks to operator / staff, samples and the environment from pathogenic biological agents (PBA) and microorganisms responsible for spreading airborne infection

TYPES:

There are three types of class 2 biosafety cabinets are made. It is the type of work which decides which class 2 BSC should be used in laboratory. Below is short description about all types:

- Type A2: recirculate approximately 70% air and 30% exhaust

- Type B1: recirculate approximately 30% air and 70% exhaust

- Type B2: Does not recirculate but exhaust 100% air

CONSTRUCTION:

These cabinets are ergonomically designed to provide long service life. Only thick metal sheets and pipes are used in construction so that you may get the finest and safest Biosafety Cabinet in the market today. There are three different MOC used.

- Complete Stainless Steel 304 / 316.

- Inner Stainless Steel, Outer Mild Steel.

- Stainless Steel bench, rest mild Steel.

AIR FILTRATION:

In order to minimize spread of airborne bacterial and viral organisms, the use of filter is crucial; therefore, we have long-life DUAL ULPA filters for supply and exhaust with 99.999% efficiency for particle sizes 0.1 to 0.3 microns in our biological class 2 type A2 safety cabinets. These air filters are of reputed brands in the market, economical in price and easy replaceable. ISO 5 / Class 100 quality, supply and exhaust through HEPA filters are done. Inflow velocity remains approx. 105 fpm (0.5 m/sec), while down flow velocity remains approx. 55 fpm (0.3 m/sec). 70 % air is re-circulated and 30% exhaust.

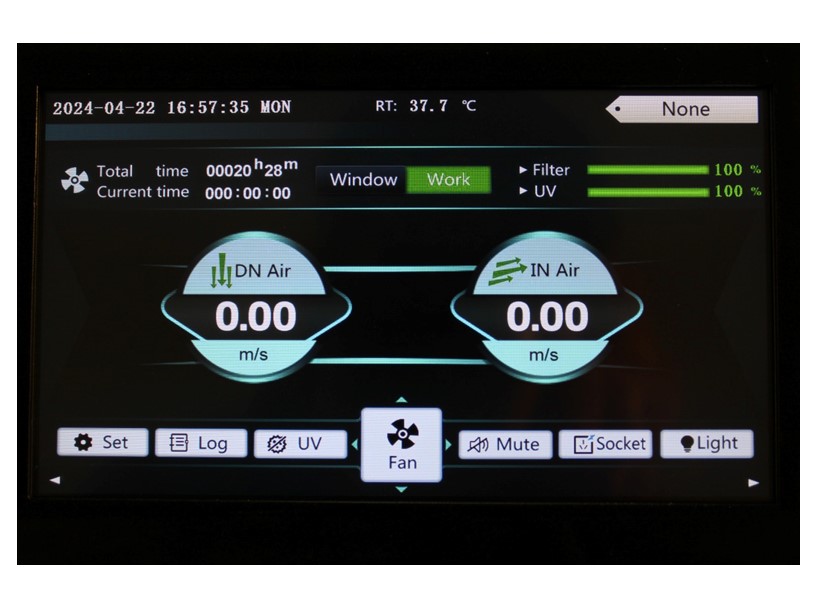

CONTROLLER:

Microprocessor based controller with 7” touch screen graphical user interface displays safety and performance data and maintenance data including the total accumulated operating hours of the unit, the total UV work hours and the UV bulb install date, the filter running time, estimated residual lifetime of the HEPA filter, and the filter install date with the slope 10° to enhance user comfort, minimize glare, and expand the user’s reach into the work area.

BLOWER:

EBM Papast German blower used in our biosafety cabinet which automatically adjusts the airflow speed without the use of a damper to ensure continuous safe working conditions even without maintenance adjustments.

STANDARD ACCESSORIES:

Our Biosafety cabinets are fitted with fluorescent lights outside working zone. UV lamps are fitted inside working zone in such a way that the operator cannot see them directly. An hour meter is connected to UV lamp. Electrical sockets are fitted to run any instrument under the working area; in addition, service fixtures for air, gas, vacuum and water are fitted on demand.

We also manufacturer biosafety cabinets class 2 type B1 and B2

SPECIFICATIONS:

| Sizes Available | 2ft, 3ft, 4ft, 5ft and 6 ft |

| Construction | Special-type bio-coating to minimize contamination and rust proof and made up of Electro-galvanized steel |

| Work top | Stainless steel type 304 |

| Side walls | Double-layered and under negative pressure |

| Sash | Sliding front sash that is UV-protected and fully open |

| Switch | ON/Off switches for Cabinet, Light & Blower |

| Air filtration | DUAL ULPA filters with maximum efficiency 99.999% |

| Air recirculation | 70% recirculation and 30% exhaust |

| Average Airflow Velocity | Air flow velocity 450 Cubic foot per min |

| Fumigation | In-built fumigation port |

| UV light | Programmable automatic UV light timers simplify operation, extend UV light life, and save energy |

| Type of illumination | Fluorescent lamp with intensity of light (1250 lux) |

| Noise level | Less than 60 decibel |

| Power supply | 220-250V/50-60Hz |

| Standard fittings | Stand made of electro-galvanized steel with castor wheels A single-piece raised armrest Magnehelic Pressure Gauge 3” port with ¼” hole on rubber membrane inside Electrical outlet socket USB port |

| Optional | Virus burnout Foot rest Calibration certificates HMI Controller |

Standard Size/ Dimension

| IG-CIIA2222 | 2 x 2 x 2 | 610 x 610 x 610 mm |

| IG-CIIA2322 | 3 x 2 x 2 | 914 x 610 x 610 mm |

| IG-CIIA2422 | 4 x 2 x 2 | 1220 x 610 x 660 mm |

| IG-CIIA2522 | 5 x 2 x 2 | 1524 x 610 x 610 mm |

| IG-CIIA2622 | 6 x 2 x 2 | 1829 x 610 x 610 mm |

Customize options are available.

Reviews

There are no reviews yet.